06/12/2025

Upcoming Guest Lectures at TU Dortmund – June 25, 2025

We are pleased to invite you to two exciting guest lectures organized by the Chair for Reliability Engineering (CRE):

🕘 09:00 (CEST)

🔹 Professor Héctor Jensen

🏛️ Universidad Técnica Federico Santa María, Valparaiso, Chile

📘 Title: On the Use of Reliability Methods and Hamiltonian Monte Carlo for Complex Identification Problems in Structural Dynamics

🕙 10:00 (CEST)

🔹 Assistant Professor Danko Jerez

🏛️ Universidad Técnica Federico Santa María, Valparaiso, Chile

📘 Title: Designing Under Competing Objectives: An Approach for Multiobjective Reliability-Based Optimization of Structural Dynamical Systems under Stochastic Excitation

📍 Location: Room SR 3.1 I, Institut für Umformtechnik und Leichtbau, TU Dortmund, Baroper Straße 299, 44227 Dortmund

💬 Can’t make it in person? No problem! Join us virtually via Zoom by registering here:

https://lnkd.in/ecwcpCtg

We look forward to seeing you there!

06/12/2025

17th Plenary Meeting in Aachen on June 17-18, 2025

The 17th Plenary Meeting of the TRR 188 will take place on June 17th and 18th at the WZL, Manfred-Weck-Haus, Steinbachstraße 19, 52074 Aachen.

11/25/2024

DFG extends the Collaborative Research Center/Transregio 188

The German Research Foundation (DFG) has announced on Monday, 25 November, that it will extend the Collaborative Research Center/Transregio “Damage-controlled forming processes” (TRR 188) for another four years.

Link: DFG Extends Transregio of TU Dortmund University and RWTH Aachen University - TU Dortmund

04/05/2024

Proposal for 3rd funding period submitted

Today the proposal for the 3rd funding period of the TRR188 has been submitted to the DFG.

12/05/2023

Visit of Prof. Kaan Inal

Professor Kaan Inal, head of the Computational Mechanics Research Group at the University of Waterloo in Canada, continued his group's collaboration with the CRC188. He contributes to the topics of modelling and characterization of damage in forming technology as a Mercator Fellow in CRC 188. During his visit, Professor Inal presented his latest research results on modeling manufacturing processes with machine learning and the failure behavior of aluminum alloys. Furthermore, he visited the research facility of the IMM and engaged in intensive discussions regarding new research questions with Dr.-Ing. Talal Al-Samman and Max Wollenweber.

11/21/2023

4th Industry Colloquium in Aachen

The 4th Industry Colloquium focused on the potentials to control damage evolution and improve component performance by process design as well as by adjusting damage tolerant microstructures. Esteemed speakers from both industry and research presented and discussed their latest findings, highlighting the potential for industrial applications and exploring the requirements and possibilities within the field.

09/19/2023

ICFG International Paper Prize for Robin Gitschel

Robin Gitschel, research associate of the Institute of Forming Technology and Lightweight Components, was awarded the "ICFG International Paper Prize 2023" at the 56th Plenary Meeting of the International Cold Forging Group (ICFG) which took place in Ankara from September 10-13, 2023. Since 1998, the prize has been awarded annually to young scientists for outstanding research results in the field of cold forging.

Mr. Gitschel received the prize for his research on damage evolution in cold forging. Using a novel modeling approach based on evolution equations to describe void nucleation, void growth, and void closure as well as a parameter identification scheme based on scanning electron microscopic measurements on forward rod extruded parts, damage distributions in cold-forged components can be predicted precisely. With the help of this simulation approach, cold forging sequences can be designed in a damage-controlled manner to produce parts with increased product performance during service life.

09/13/2023

Retirement of Prof. Gerhard Hirt

As spokesperson of the second funding period, Prof. Gerhard Hirt led TRR 188 with great commitment and success until his retirement on September 1, 2023. To ensure a smooth transition, the spokesperson's office was transferred to the deputy spokesperson of the TRR 188, Prof. A. Erman Tekkaya, on July 1, 2023. He already held the position of spokesperson during the first funding period and could, therefore, continue the business of TRR 188 seamlessly.

07/10/2023

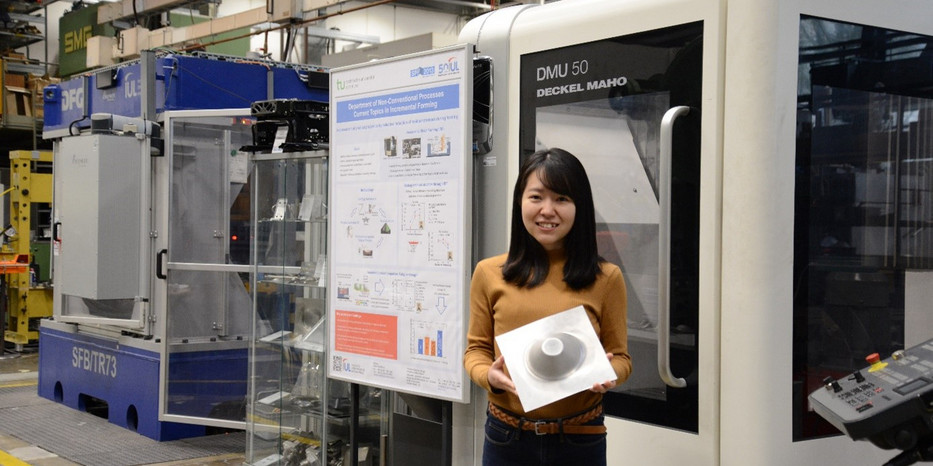

Alexander von Humboldt Fellow Dr. Shiori Gondo at the IUL

Dr. Shiori Gondo (National Institute of Advanced Industrial Science and Technology, Japan) contributes to TRR 188 during her 2-year Alexander-von-Humboldt fellowship at IUL. Her research focuses on Incremental Sheet Forming, aiming to suppress void formation and enhance the formability and product performance of high-strength steel components. Her past work on analyzing and predicting microstructure evolution in forming is also relevant for TRR 188.

05/31/2023

Doctoral Examination of Alexander Schowtjak

Congratulations to Mr. Alexander Schowtjak on having successfully passed his doctoral exam. On May 26, 2023, numerous listeners attended the doctoral presentation entitled "Prediction of pore development in forming technology" by Mr. Schowtjak. Prof. Dr.-Ing. S. Münstermann traveled from RWTH Aachen University to Dortmund as a reviewer of the PhD exam. In addition, Prof. Dr.-Ing. A. E. Tekkaya as supervisor of the dissertation, the chairman Jun.-Prof. Dr.-Ing P. Woizeschke from ISF, and the examiner Prof. Dr.- Ing J. Mosler were members of the examining commission.

03/20/2023

Visit of Junhe Lian

Junhe Lian from Aalto University, Finland was a guest at the IEHK in Aachen. As an expert in material modeling, damage, and failure at both the macroscopic and microscopic levels, Prof. Lian was able to contribute his knowledge to the TRR. During his stay, Prof. Lian gave lectures in Aachen and Dortmund on modeling anisotropic plasticity behavior and the characterization and modeling of stress state-dependent failure at cryogenic temperatures.