Summary

The primary goal of the scientific service project S01 is to facilitate the collaboration among the individual projects and project areas with particular focus lying on the implementation, calibration and validation of damage models. The service project ensures the transfer of the knowledge gained in project area B (material characterization) and of the simulation approaches developed in project area C (modeling) to the process simulations carried out in project area A (process technologies).

In the 1st funding period (FP), established local damage models were implemented into the commercial software Abaqus and calibrated based on experimental data. Additionally, a framework to account for gradient-enhanced damage models in Abaqus was developed so as to enable process simulations with the non-local damage models developed in project area C. In the 2nd FP, particular focus was laid on the extension of the framework to coupled multi-physics problems, including the thermo-mechanically coupled, gradient-enhanced damage models developed in TRR 188. Additionally, a data-driven post-processing tool was developed to predict the void area fraction based on forming simulations and to establish a link between simulations and experiments. The developed parameter identification tool ADAPT was made available as an open source code with a detailed documentation on GitHub. Based on ADAPT, an efficient model calibration process was established and material parameters for the TRR 188 materials DP800 and 16MnCrS5 were identified. Additionally, a hybrid parameter identification strategy was developed, which makes use of a pre-trained neural network to determine “optimal” starting values for the optimization problem so as to further enhance the quality of model calibrations. Since the main objective of the scientific service project S01 is to ensure the applicability of the damage models developed in project area C, the provided simulation frameworks are extended in the 3rd FP to cover a broad range of applications. To contribute to this objective an explicit solution framework for gradient-enhanced damage models is developed. Additionally, the performance of the simulation frameworks is enhanced by the incorporation of a physics informed neural network into the finite element analysis that enables an efficient solution of the micromorphic field equation. Furthermore, the data-driven model for damage evolution that was developed in the 2nd FP is extended to non-monotonic loading paths and physical augmentation is considered in the form of a thermodynamically consistent neural network. The damage evolution law is additionally linked to elastic and plastic properties to quantify the influence of the void area fraction on the macroscopic product properties. The calibration of damage models remains an important objective of the scientific service project in the 3rd FP. More specifically speaking, it was revealed that the parameter sets identified by TRR 188 are sensitive with regard to deviations in the input data. Uncertainty quantification methods are used to investigate this sensitivity, to determine confidence intervals for the identified material parameters and to study the necessity of (numerically expensive) model extensions. The parameter identification framework is further extended by considering non-isothermal calibration experiments.

Development of the research within the project S01

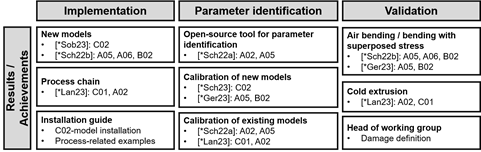

The scientific contributions of the project in the areas of model implementation, parameter identification for (damage) models, validation of model predictions for forming processes and the service aspects are summarized in Fig. 1.

Fig. 1: Overview of contributions made and supported by project S01 in TRR 188.

In order to enable the technology projects to use the macroscopic damage models developed in project area C, the scientific service project prepared an instruction manual with application examples of relevant forming processes. By using the non-local damage models, mesh-objective predictions of damage evolution in forming processes are made possible. In addition, novel numerical frameworks and models were developed and implemented: To consider forming processes at elevated temperatures, the Abaqus framework for non-local damage models that was developed in the 1st FP was extended to solve coupled three-field problems. Furthermore, a data-driven model to predict the void area fraction was developed, which can be used to quantitatively estimate the damage distribution in forming processes. For the developed models (non-local damage model [Spr23], thermo-mechanically coupled gradient-enhanced damage model [*Sob24]) to be applied in TRR 188, material parameters had to be identified based on experimental data. The significant increase in model complexity compared to the classic damage models used in the 1st FP rendered the development of sophisticated optimization strategies necessary. A computational framework based on neural networks was developed to obtain physical meaningful starting values for multi-objective parameter identification. Furthermore, high-resolution SEM measurements of void area fractions were included in the parameter identification process, thereby improving the quantitative prediction of damage in forming processes. For model validation, which involves verifying the suitability of a model for a specific application case, data such as density measurements, load-displacement curves, displacement fields, and high-resolution representative microstructure images were utilized. The models were used for damage prediction in the forming processes investigated in TRR 188, including extrusion (A02), free bending (A05), bending with superposed stresses (A05) and deep drawing (A06). In comparison to the validation in the 1st FP, the prediction of damage in the form of void area fractions was improved both qualitatively and quantitatively.

Parameter identification based on ML/ANN

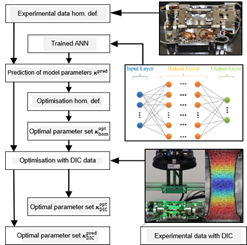

The determination of “suitable” starting values is an integral part of the material parameter identification process and was in the focus of this work package. Specifically speaking, a computational framework based on a neural network was developed to obtain physical meaningful starting values for multi-objective parameter identification (Fig. 2). In the offline phase, the neural network is trained with data obtained from the considered material model for homogenous deformation states. In the online phase, the network is evaluated for experimental data (based on homogenous deformation states) so as to obtain an accurate initial prediction of the material parameters. Subsequently, the parameter identification framework ADAPT [*Sch22a], which was developed in the 1st FP is applied. The parameter predictions of the neural network are used as starting values for this multi-objective optimization scheme. A major benefit of this strategy is that the neural network only has to be trained once for a considered material model (offline phase) and can efficiently be evaluated for different materials and experimental data in the online phase. As an application example, the network was trained in a first step for (a local version of) the finite strain gradient-enhanced ductile damage model developed in project C02. In a second step, the network was applied to the experimental data recorded in the projects C02 and S01, and the material parameter sets for the two TRR 188 materials DP800 and 16MnCrS5 were determined. Various strategies for generating training data for the neural network were investigated, compared and suitable parameter sets were identified [*Sch23].

Fig. 2: Conceptual visualization of the hybrid parameter identification strategy based on a neuronal network [*Sch23].

A multi-instance approach for gradient-enhanced damage formulations in thermomechanics (IM)

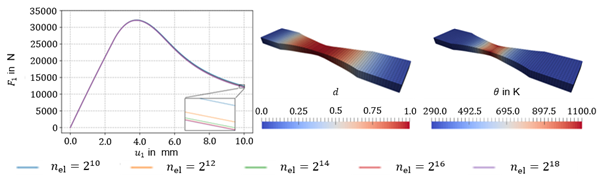

To make the sophisticated material models developed in project area C available for the process technology projects, the implementation of these models into commercial software is a key objective of project S01. The implementation of gradient-enhanced damage models such as the ones developed in project C02 into commercial finite element software is a challenging task, since these models are intrinsically based on the introduction of an additional field equation of micromorphic-type. In the 1st FP, an implementation framework was developed [Ost19], which solves the resulting two-field problem based on a thermo-mechanically coupled Abaqus user material (UMAT and UMATHT). The additional micromorphic field equation is solved by utilizing the heat equation. A major drawback of this procedure is its limitation to two coupled field equations. As a consequence, the solution of a classic heat transfer problem in conjunction with a gradient-enhanced damage model is not possible in the proposed framework. Since the investigation of temperature-damage interactions (A-projects) and the development of temperature-dependent damage models (C-projects) are main objectives of the TRR 188 in the 2nd and 3rd FP, an extended solution framework is required. Against this background, an Abaqus-based approach was developed to solve three (and potentially more) coupled field equations. The implementation is still based on a user material and consequently allows for the usage of several Abaqus features, such as complex contact algorithms and continuum as well as structural element formulations [*Sob24]. To solve the considered three-field problem based on a thermo-mechanical user material, two coupled domains are considered. On each of those, the balance of linear momentum and a heat-equation-type field equation are solved. The solution approach is referred to as a two-instance formulation [*Sob24]. Both instances (primary and secondary) are coupled by introducing linear constraints on the deformation field. In this regard, the secondary instance can be interpreted as a follower domain that is solely used for the solution of the damage-related field equation. To investigate the performance of the two-instance formulation and to assess its applicability, a thermo-mechanically coupled, gradient-enhanced, quasi-brittle damage model was implemented. The applicability of the proposed appraoach is exemplified by the classic reduced section plate problem in Fig. 3. To asses the mesh-dependency of the solution, the global reaction force for different meshes is presented. Furthermore, the mesh-objective predictions for the damage and temperature field are shown. The theoretical foundations, the algorithmic framework and extensiv mesh convergence studies are provided in [*Sob24]. Additionally, the two-instance formulation is made available as an open source code on GitHub. It is noteworthy that the formulation is not limited to a specific application or a specific number of coupled field equations.

Fig. 3: Solution of a classic reduced section plate problem for a thermo-mechanically coupled, gradient-enhanced, quasi-brittle damage model, reproduced from [*Sob23]. Left: Reaction force as a function of elongation for various discretizations. Right: Predicted damage and temperature fields.

Efficient simulation tools and (adaptive) model order reduction (IM)

Due to the (numerical) complexity of process simulations that often times include non-simple contact problems, implicit finite element solvers show a non-optimal convergence behavior and severe instabilities. To address this problem, the objective of the current work was to make the macroscopic damage models developed by C02 available in Abaqus explicit. The regularization strategy of the C02 model is based on gradient-enhancement (micromorphic approach), which requires the solution of an additional elliptic partial differential equation. Since Abaqus explicit is only capable of solving hyperbolic and parabolic partial differential equations, the implementation of the gradient-enhanced damage model for the explicit solver is not trivial. To make the ductile damage models developed by project C02 available for the process projects, the regularization strategy of the model was thus adjusted. In particular, a viscous-type regularization, resulting in rate-dependent damage evolution, was considered. The viscous regularization strategy yielded mesh-objective results and was implemented in Abaqus/Explicit by making use of a user material-based approach. Based on these developments, a viscous regularization of the ductile damage model developed by project C02 is in the focus of ongoing work. Evidently, the introduction of viscos effects that are rather of numerical than of physical origin significantly changes the underlying physics and results, for instance, in loading rate sensitivity, see also [Lan22]. Motivated by these drawbacks of viscous approaches towards the regularization of localization phenomena in continuum mechanics, focus in the 3rd FP is on the reformulation of the original, gradient-enhanced damage formulation. In particular, additional “micromorphic inertia terms” are included so as to change the type of the governing partial differential equation.

General framework for the parameter identification based on microstructure data (IUL)

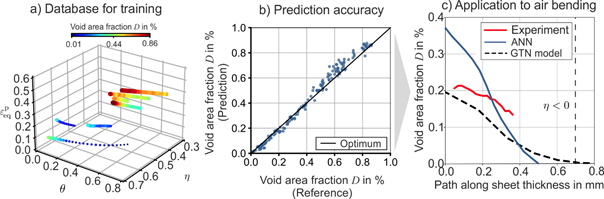

In the context of calibrating damage models, load-displacement curves and displacement fields are commonly employed, whereas microscale data directly linked to damage in the sense of void fraction are not utilized [Woe20]. Consequently, the underlying damage evolution often lacks the real description of void volume or void area fraction. To address this limitation, the existing in-house parameter identification framework has been extended to facilitate the calibration of various damage models and incorporate data of the microstructure into the objective function of the optimization problem [*Sch22a]. The optimization considers integral data such as load-displacement curves, full-field data such as strain- and displacement fields and void measurements at the micro scale. Additionally, contour data can be incorporated into the objective function instead of displacement fields. This is particularly relevant when calibrating using round samples. By assuming isotropy and a perfect specimen geometry, the field data, due to its rotational symmetry, contains redundant information that can be reduced to one-dimensional surface data. The material parameters of the Gurson-Tvergard-Needleman (GTN) model and the Lemaitre model were identified for both a dual-phase steel DP800 and the case-hardened steel 16MnCrS5. As the damage evolution in each model is directly linked to the void volume fraction and void area fraction, respectively, it is possible to integrate the experimental data on void area fractions obtained from projects B02 and B04 into the calibration process. The calibrated models exhibit the capability to predict both the macroscopic load-displacement curve and the microscale evolution of ductile damage. This has been validated on different forming processes, e.g. air bending (data provided by A05), where for the first time the void area fraction could be predicted quantitatively (Fig. 5c). The developed parameter identification tool, called ADAPT, has been made freely available as an open-source tool on GitHub. Beyond the defined tasks of this work package, the general challenge to generate adequate starting values for a multi-objective optimization procedure has been addressed by employing the machine-learning assisted framework (previously described) to predict the initial start values for a subsequent parameter identification.

Prediction of product performance (IUL)

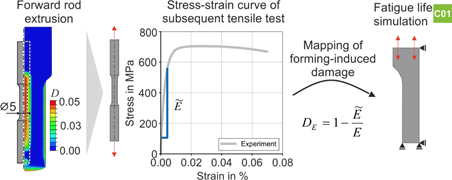

Depending on the application of the final product, its performance is primarily evaluated based on its energy absorption during crash and on the fatigue life under cyclic loading [Das20]. To investigate the product performance in both cases forward rod extrusion with varying shoulder opening angles was considered so as to to isolate the effect of ductile damage from other factors. Using the calibrated damage models obtained in WP6, the damage evolution during forward rod extrusion was predicted (Fig. 4). The simulations demonstrated that by altering the shoulder opening angle, the triaxiality, and thus the damage on the central axis, could be reduced. Experimental Charpy impact tests from project A02 confirmed that reducing the damage positively influenced the energy absorption. Simulations of the Charpy impact test have not been performed yet, instead, the remaining focus was set on the prediction of the fatigue life performance of forward rod extruded components. Together with project C01 a novel constitutive model considering forming-induced damage and subsequent fatigue damage has been developed [*Lan23]. Project S01 has devised the mapping strategy and corresponding algorithms to translate the forming-induced damage occuring during extrusion as an initial state to the numerical model of a subsequent tensile test under low-cycle-fatigue (LCF) loading (Fig. 4). Forming-induced ductile damage is related to measurements of void area fraction, density, and degradation of Young’s modulus. The latter property is used to account for the forming-induced ductile damage in the fatigue life simulation with , where is the initial Young’s modulus and defines the apparent Young’s modulus determined in subsequent tensile tests of forward rod extruded components. In this way, the fatigue life model is able to capture the effect of forming-induced damage on the degradation during the service life.

Fig. 4: Workflow of the mapping routine to account for the forming-induced damage distribution in the subsequent fatigue life simulation. The fatigue life simulation has been performed by project C01.

Prediction of ductile damage using artificial neural networks (IUL)

The above mentioned database served as the foundation for the development of a damage model for the prediction of ductile damage in the sense of void fractions using artificial neural networks (ANN) (Fig. 5a) [*Sch22b, *Ger23]. The model development was done in close cooperation with the Computational Mechanics Research Group (CMRG) of Mercator Prof. Kaan Inal. The ANN model depicts the damage evolution in DP800 solely based on experimental void measurements, particularly void area fractions and thus, unlike conventional constitutive models, is not subjected to assumptions regarding the damage evolution law for the training of the neural network. Furthermore, suitable training and prediction strategies were developed to enable the prediction of damage evolution based on the loading history. The optimization of the hyperparameters of the ANN, as well as validations against unseen data, were performed to ensure optimal training of the neural network. The data-driven damage model exhibits robust predictive accuracy for training data across all magnitudes of void area fraction (Fig. 5b). Finally, the model was applied to various sheet forming processes. It successfully predicts the void area fraction in air bending and performs similarly to a classical Gurson-Tvergaard-Needleman (GTN)-model that has been calibrated on experimental void measurements (Fig. 5c). However, it could be observed that the prediction quality depends on the experimental and numerical data used for training. If the loading states of the application problem are within the domain of the training data, the prediction quality is good and even better than constitutive models used in literature [*Sch22b].

Fig. 5: a) Visualization of the experimental data points of the calibration tests used for training of a neural network. b) Prediction accuracy of the training data of the developed artificial neural network. c) Damage evolution in air bending for the neural network and a classical FEM analysis using a GTN-model. The GTN-model was calibrated on experimental void measurements as well.

Conclusion and Outlook

In the 2nd FP the service project S01 has contributed to the scientific findings of the TRR 188 by integrating experimental data of project area B and the damage models of project area C into the process investigations of project area A. The existing parameter identification tool has been extended to incorporate microstructural data within the optimization scheme. Additionally, a neural network-based approach for initial start value prediction was integrated to enhance efficiency. Ultimately, several damage models for the TRR 188 materials DP800 and 16MnCrS5 have been successfully calibrated. Furthermore, the S01 project developed tailored models and simulation approaches: Firstly, an efficient Abaqus implementation for thermo-mechanically coupled gradient-enhanced damage models was pursuit, enabling the simulation of forming processes under non-isothermal conditions (A02, A04) and of damage-temperature interactions. Secondly, a data-driven post-processing tool to predict damage evolution has been developed. In the 3rd FP, focus in the field of parameter identification is laid on the uniqueness of the determined parameter sets by using a Bayesian quantification, and on process-related calibration to improve the quantitative prediction of damage in forming processes. Based on the implementation of the thermo-mechanically coupled damage model, the model robustness and efficiency will be improved by explicit solution schemes and physics informed neural networks. Furthermore, the data-driven damage model will be extended to include non-monotonic loading paths and a link between the mechanical properties and the damage evolution will be established. Finally, the influence of the void characteristics on the mechanical properties will be investigated.

References

[Das20] Das, B.; Singh, A.; Kumar, P.: Low cycle fatigue performance of DP600 steel under various pre-straining paths. International Journal of Fatigue 132 (2020) 105331.

doi: 10.1016/J.IJFATIGUE.2019.105331.

[*Ger23] Gerlach, J.; Clausmeyer, T.; Schowtjak, A.; Muhammad, W.; Brahme, A.P.; Koppka, L.; Inal, K.; Tekkaya, A.E. Data-driven ductile damage model for damage-induced material degradation in forming. Manufacturing Letters 35 (2023) 1097-1102. doi:10.1016/j.mfglet.2023.08.092.

[Lan22] Langenfeld, K.; Kurzeja, P.; Mosler, J.: How regularization concepts interfere with (quasi-)brittle damage: a comparison based on a unified variational framework. Continuum Mechanics and Thermodynamics 34 (2022) 1517-1544. doi: 10.1007/s00161-022-01143-2.

[*Lan23] Langenfeld, K.; Lingnau, L.; Gerlach, J.; Kurzeja P.; Gitschel, R.; Walther, F.; Kaiser, T.; Clausmeyer T.: Low cycle fatigue of components manufactured by rod extrusion: Experiments and modelling. Advances in Industrial and Manufacturing Engineering 35 (2023) 100130. doi:10.1016/j.aime.2023.100130.

[Ost19] Ostwald, R.; Kuhl, E.; Menzel, A.: On the implementation of finite deformation gradient-enhanced damage models. Computational Mechanics 64 (2019) 847-877. doi: 10.1007/s00466-019-01684-5.

[*Sch20] Schulte, R.; Ostwald, R.; Menzel, A.: Gradient-enhanced modelling of damage for rate-dependent material behaviour – A parameter identification framework. Materials 13 (2020) 3156. doi: 10.3390/ma13143156.

[*Sch22a] Schowtjak, A.; Schulte, R.; Clausmeyer, T.; Ostwald, R.; Tekkaya, A. E.; Menzel, A.: ADAPT – A Diversely Applicable Parameter Identification Tool: Overview and full-field application examples. International Journal of Mechanical Sciences 213 (2022) 106840. doi: 10.1016/j.ijmecsci.2021.106840.

[*Sch22b] Schowtjak, A.; Gerlach, J.; Muhammad, W.; Brahme, A.P.; Clausmeyer, T.; Inal, K.; Tekkaya, A.E.: Prediction of ductile damage evolution based on experimental data using artificial neural networks. International Journal of Solids and Structures 257 (2022) 111950. doi: 10.1016/j.ijsolstr.2022.111950.

[*Sch23] Schulte, R.; Karca, C.; Ostwald, R.; Menzel, A.: Machine learning-assisted parameter identification for constitutive models based on concatenated loading path sequences. European Journal of Mechanics – A/Solids 98 (2023) 238-242. doi: 10.1016/j.euromechsol.2022.104854.

[*Sob24] Sobisch, L.; Kaiser, T.; Furlan, T.; Menzel, A.: A user material approach for the solution of multi-field problems in Abaqus: Theoretical foundations, gradient-enhanced damage mechanics and thermos-mechanical coupling. Finite Elements in Analysis and Design 232 (2024) 104105. doi: 10.1016/j.finel.2023.104105

[Spr23] Sprave, L.; Menzel, A.: A large strain anisotropic ductile damage model - Effective driving forces and gradient-enhancement of damage vs. plasticity. Computational Methods in Applied Mechanics and Engineering 416 (2023) 116284. doi: 10.1016/j.cma.2023.116284.

[Woe20] Woelke, P., Simplification of the Gurson model for large-scale plane stress problems. International Journal of Plasticity 125 (2020) 331-347. doi: 10.1016/j.ijplas.2019.10.004.