First of all the aim of the TRR 188 is to understand the mechanisms of material damage during the forming process. Furthermore, the TRR 188 intends to quantitatively predict the damage evolution and to specifically adjust the damage states with regard to component performance. For this purpose, an interdisciplinary consortium of forming technology, materials science, and material testing technology as well as mechanics develops new

-

methods for the modeling of the damage development along the forming process chain, taking into account material-physical relationships,

-

technologies for the quantitative assessment of damage, and

- technologies for technical use.

Based on the guiding principle of the CRC/Transregio

"Damage is not a failure"

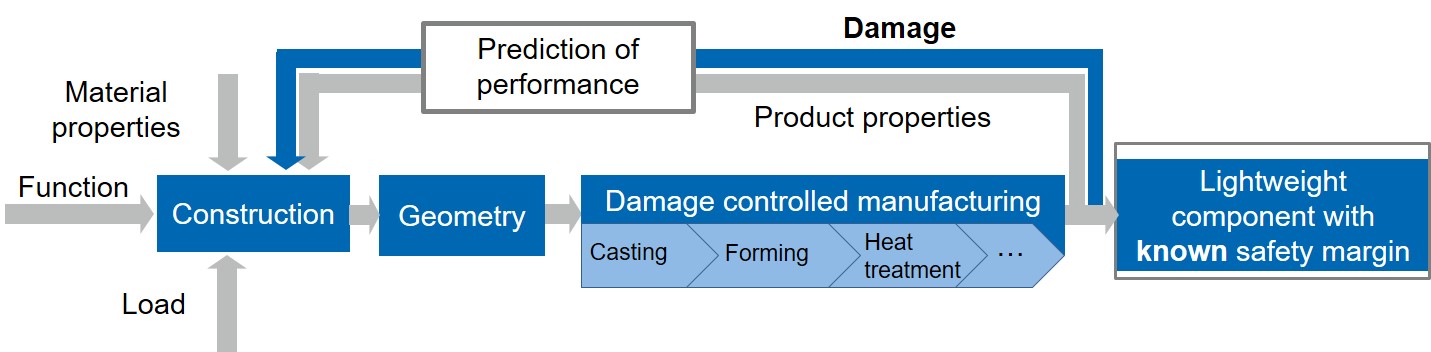

two paradigm shifts are targeted. In product and component design, actual production-induced component properties, including damage, should be taken into account instead of the nominal material properties. The design of the forming processes should no longer be based only on the manufacturability or the maximum possible failure-free formability of the material, but should aim at optimizing the microstructural damage state with respect to the maximum performance of the products. Damage-controlled design of the forming process chain ensures that the component is not only macroscopically free of defects and meets conventional quality requirements, but is also characterized by the best possible mechanical properties and a higher load-bearing capacity.

Damage-based component design

The future vision of the TRR 188 is to realize new lightweight products and concepts with tailor-made and guaranteed performance in the long term by the targeted adjustment and precise quantification of the actual damage level. This new generation of lightweight construction is characterized by a reduced mass compared to the state of the art while at the same time guaranteeing higher reliability during service life.