The processing of the overall objective takes place in three successive funding periods of four years each.

The concept of scientific work underlying all funding periods is based on the selection of representative process chains for bulk and sheet metal forming and the associated standard material concepts. On the basis of the material concepts, the damage development is continuously characterized and numerically modeled on all scales relevant to engineering science understanding.

In the first two funding periods, it has been shown for many typical sheet and bulk forming processes that it is possible to influence and, if necessary, actively control damage through process modifications. Based on a deep understanding of microscopic damage mechanisms, the local evolution of damage as a function of the global process parameters can reliably be predicted with physics-based modeling and advanced simulation. Using representative components of cold extruded 16MnCrS5 steel, the stiffness was increased by 10%, the number of load cycles to failure by 20% and the notched bar impact energy by as much as 80%, by redesigning the forming processes to reduce the void area fraction deterministically. These significant performance improvements have been achieved by tailored process layouts, primarily shifting the load path towards negative stress triaxiality. Using increasingly complex process sequences and component geometries, the Lode parameter (i.e., the magnitude of the intermediate principal stress relatively to the max. and min. ones) was revealed quantitatively as an additional influencing variable for control. Recrystallization and other thermally-activated mechanisms have a significant influence on the resulting damage in both hot forming of components, as well as during subsequent heat treatment of cold-formed components. It was found that the rolling of semi-finished products enables the creation of a damage-resistant microstructure, to the benefit of subsequent forming: suitable thermomechanical process control during rolling of automotive high strength steel DP800, for instance, can eliminate banded structures, improving its damage-tolerance. These and further achievements were made possible through seamless collaboration among the three project areas: “A-Process Technology”,

"B-Characterization” and “C-Modeling". Novel characterization methods developed in the B-area enable the effective evaluation of formed components produced by the A-area, as well as the parameter identification and validation of the models developed and deployed by the C-area. Three industrial transfer projects (T-projects) were initiated in the 2nd funding period that enabled the early transfer of knowledge to industrial applications.

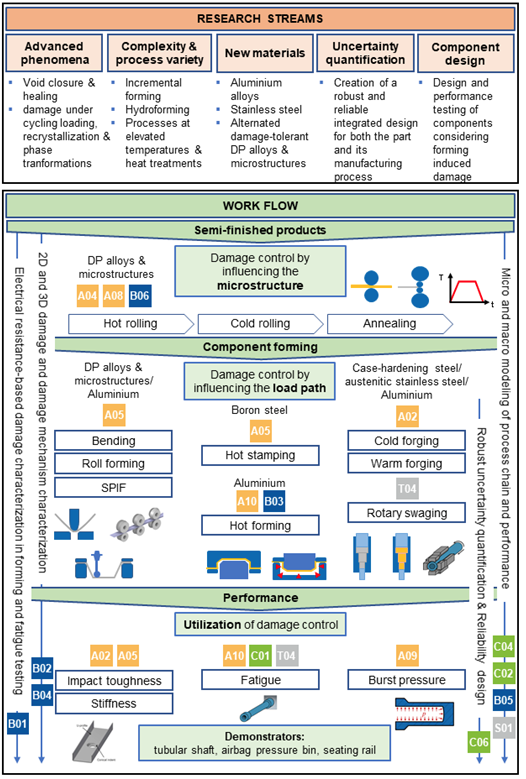

In the planned 3rd funding period, in direct expansion of the above-mentioned work, investigations in the three project areas A-B-C will be structured along five main streams:

- Discovery and mapping of damage phenomena, e.g., void closure and healing, cyclic loading, phase transformations and recrystallization. The ambitious target to design lightweight components near their limit loads also requires a systematic analysis of the uncertainty and sources of scatter.

- The forming process stream will increase the process complexity and diversity, by including incremental forming, hydroforming and elevated temperature forming (beyond rolling, cold forging, bending and deep drawing). Press hardening of sheets, which is increasing the physical and technological complexity of the knowledge horizon of TRR 188, will remain a focus.

- The materials stream will extend our findings about typical steels to aluminum AA6010 and 6082, as important materials for lightweighting. For press hardening, the industry-typical 22MnB5 steel will be analyzed. In addition to the commercially-available materials, steels with self-designed and manufactured damage-resistant microstructures will be produced in semi-finished product dimensions, to demonstrate their damage tolerance in further processing and service.

- In the modeling stream, the next generation of damage models, that include void morphology, will be created. Healing and heat treatment extensions of the damage models will be developed. Data-based prediction of damage will be significantly extended, and will be accompanied by enhanced parameter identification methods, including their uncertainties.

- The final stream is the design of components enhanced by the knowledge of damage and its variability, including its sources. Focus will be on the performance modeling of components by coupling the forming-induced damage with damage during service, e.g., impact or fatigue.

To achieve these goals three new sub-projects A09, A10 and C06 are planned.