Summary

During the 2nd FP of the collaborative research center TRR188, the findings of the 1st FP were transferred to an industrial application: manufacturing Monobloc Tubular Shafts (MTS) at GKN Automotive, with the numerical support of Hexagon. The process chain of incremental radial forging and subsequent spline extrusion with heat-treatment steps was investigated in the transfer project T01. Damage evolution depending on the process parameters during radial forging and spline extrusion and the influence of heat treatment have been determined in this industrial application. Numerical simulations of the first process in the chain, radial forging, showed that material zones in the hollow shaft exhibit alternating positive and negative stress triaxiality during a hammer stroke. Damage in the formed tube can be controlled with the hammer velocity and angular increment during radial forging. With an increase in the radial feed velocity the density of the part decreases, indicating that the void volume and, thus, damage in metal increases. However, additional effects like the influence of load-path changes and strain rate on the flow curve of the workpiece material and the subsequent damage evolution were not part of the investigation. It was also observed that radial forging leads to cracks on the surface of the shaft along the axial direction. In-situ investigations showed that multiple load-path changes lead to decohesion of the non-metallic inclusions from the steel matrix. The second process in the chain is the axial forming process, i.e., spline extrusion. The numerical analysis in T01 revealed the presence of zones with positive stress triaxiality near the flank zone of the die shoulder-opening and on the inner contour of the hollow shafts. Hence both the outer and inner surfaces are critical in radial forging and also in spline extrusion. In the final step, the shafts are heat-treated to transform the 34MnB5 ferritic-pearlitic microstructure into a martensitic microstructure. Such a heat treatment led to the formation of MnO inclusions in the shaft with local ferritic zones. Metallographic investigations of the hardened specimen showed the presence of a higher density of voids, with a high aspect ratio. Due to stress localization, the shape of voids plays a vital role in fracture initiation during service under dynamic loading.

The new transfer project T04 aims to investigate all the new phenomena discovered in T01 and to demonstrate at the end of a damage-controlled industrial process chain, a complex component with measurable higher performance. The new phenomena to be investigated cover the analysis of damage mechanisms and their interaction with other physical effects occurring specifically in the manufacturing of MTS. Specifically, during radial forging the cyclic Bauschinger effect interacts with the evolution of the void area fraction, because multiple hammer strokes affect the stress state for the void evolution. In the contact area of the hammers and the workpiece, distinct zones of increased local strain rate are observed in radial forging. This phenomenon is referred to as strain localization and can be analyzed with the help of classical slip-line theory. In the subsequent heat-treatment steps of the MTS phase transformation occurs, which induces additional void evolution due to the interaction of the previous forming and the phase transformation from ferrite-perlite to austenite and the final martensitic microstructure. Depending on the process parameters of radial forging, micro-cracks appear at the surface of the shafts. Subsequently, during spline extrusion, these radial surface cracks orient along the material flow direction. During the heat treatment, MnO inclusions form in the cracks through diffusion. These phenomena affect the properties, e.g., fatigue life of the product. Therefore, their interaction needs to be investigated in detail. The goal of this proposal is to separate the influence of each of these single effects on the evolution of voids.

To separate the influence of damage and the Bauschinger effect on the product performance for multiple cycles of load reversal, which is typical for radial forging, the Bauschinger effect will be characterized in cyclic torsion experiments (WP1) and the damage evolution will be analyzed by density- and void area measurements. The product performance will be determined with Charpy impact tests at the IUL and performance tests at GKN. In the T01 project, high strain rates along the zones of localized strains were observed. The influence of strain localization on damage will be investigated with notched tensile specimens and with a simplified radial forging process (WP2). It is assumed that the surface cracks, which occur on the inner and outer sides of the MTS during radial forging, can be influenced by the process parameters. The investigation of the influence of process parameters on micro-cracks and the influence of inclusions and damage on the growth of surface cracks will be investigated in a simplified experiment of radial forging (WP3). Supplementary in-situ measurements of the void area during tension-compression tests at the C01 project will reveal the interaction of surface cracks with inclusions and the influence on damage. Finally, the gained knowledge of cyclic load reversal, strain localization, phase transformation-induced damage, and surface cracking and their influence on damage will be used to develop a suitable method to control damage in the process chain for the manufacture of MTS. In collaboration with Hexagon, a FEM-based approach for the prediction of damage will be validated on the process chain at GKN (WP4). It is expected that new strategies, like an adapted radial forging process and modifications in the spline extrusion process, can be used to reduce damage and increase the product performance, or reduce its weight. By the application of knowledge from all the FPs on an exemplary industrial process chain, with complex forming processes, the damage measurements and performance tests will demonstrate the potential of damage-controlled forming.

Current state of research and preliminary work

The current project T01 with the industrial partners GKN and Hexagon was initiated during the 2nd FP of the TRR. Radial forging and spline extrusion were investigated with 34MnB5 seamless hollow MTS. After forming, the shafts are heated above the austenitization temperature, quenched, tempered and coated, to increase strength and wear resistance. The current state of research and results

from project T01 and the additional preliminary work for the proposed T04 project are presented in the following.

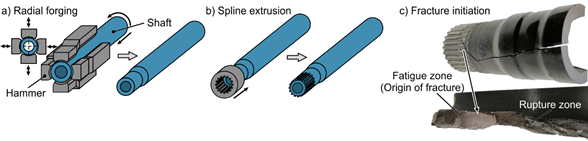

Radial forging

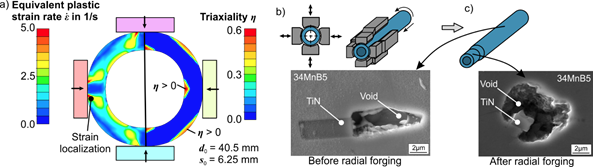

In the beginning of the process chain, a seamless tube is incrementally formed in the radial forging process described by Hustedt [Hus03]. Four hammers, each driven by an eccentric press, oscillate with a frequency of 1200 rpm and move towards the shaft with a defined radial-feed velocity. The shaft rotates during the oscillating hammer stroke (Fig. 1a) with a defined angular increment. The radial-feed velocity of each hammer and the angle of rotation between successive hammer strokes are the two important parameters for radial forging which can be varied during the process. After radial forging, gears are formed on both ends of a shaft using cold spline extrusion (Fig. 1b). Exemplary fractographic investigations on failed final products (Fig. 1c) have shown the presence of fracture initiation zones near the outer surface of the splines.

Fig. 1: Radial forging of shafts with varying cross sections and spline extrusion to produce external spline gears [*Rak23b].

Damage localization in radial forging

An upper bound method to estimate the stress state in the areas which are in contact with the hammers in radial forging was formulated by Ghai et al. [Gha06]. However, the stresses need to be considered over the complete cross section for the analysis of damage. Numerical simulations, using an isotropic elastic-plastic material model, revealed zones of alternating positive and negative stress triaxiality along the internal and external surfaces. Strain localization occurs during radial forging. Lyckström et al. [Lyc78] investigated large-scale indentation on aluminum and steel and observed similar strain localization near the hammer impact along two orthogonal lines. With higher hammer velocity the strain localization increases. Similarly in radial forging, two nearly perpendicular shear bands emerge out of the hammer contact zone (Fig. 2a). The shafts investigated in T01 showed in the initial state non-metallic inclusions along with voids (Fig. 2b), which increased in size after forming (Fig. 2c). In ductile metals, the number of voids around nonmetallic inclusions (NMIs) increases along the shear bands before failure [Bar08]. During the forming processes, the NMIs orient along the material flow direction. Singh et al. [Sin21] showed that the morphology and distribution of non-metallic inclusions around the fracture surface had a close relationship with the dynamic strength performance of the products. Summers et al. [Som04] could determine the NMIs’ diameter and orientation after hot rolling AISI 1070 steel. Gusenbauer et al. [Gus14] also used micro-CT investigations for nonmetallic inclusions characterization in steel. Hence, the orientation of voids and NMIs is crucial for the product performance. Damage generation along such non-homogeneous stress states due to strain localization has not been investigated and is currently not part of the TRR188.

Fig. 2: a) Localized strain and triaxiality during radial forging and damage sites in b) initial and c) formed material.

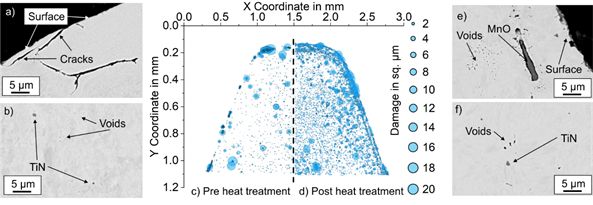

Spline extrusion and martensitic hardening

After the radial forging process, the tubular shafts are extruded through a die, which has the contour of the teeth. The forming zone is concentrated over the flank region of the teeth [*Rak23a]. The stress triaxiality is positive in the flank region, causing increased damage evolution during spline extrusion. In addition, surface cracks are observed after the spline extrusion process (Fig. 3a), similar to the ones observed after radial forging. TiN inclusions with voids were observed in the middle section (Fig. 3b). Metallographic investigations revealed the presence of higher void area fractions near the outer surface of the flank section, and surface cracks (Fig. 3c). The shafts were heat-treated to obtain an overall martensitic phase structure. After the martensitic phase change, the number of voids increased (Fig. 3d), with the presence of newly formed MnO inclusions (Fig. 3e).

Fig. 3: a) Surface cracks on the flank surface in pre-heat-treated specimen, b) voids and nonmetallic inclusions in a middle section of a pre-heat-treated tooth, c) void area fraction in a pre-heat-treated tooth, d) void area fraction in a post-heat-treated tooth, e) sub-surface voids with MnO inclusions on the flank surface in a post-heat-treated specimen, f) voids and nonmetallic inclusions in a middle section of a post-heat-treated tooth, adapted from [*Rak23b].

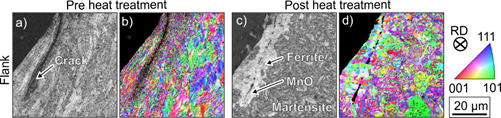

SEM investigations, conducted by project B04, revealed a ferritic microstructure near the external surface with a close association with the MnO inclusions Fig. 4. As stated by Calcagnotto et al. [Cal11], manganese in steel is an austenite stabilizer during annealing since it reduces the homogenization temperature and increases the solubility of carbon in steel. The formation of MnO inclusions depletes manganese from the nearby metal. Surface decarburization along with the depletion of manganese from the nearby metal destabilizes the austenite; hence promoting the formation of ferrite instead of martensite. The outer layer of the tooth is primarily ferrite, which wears off during the lifecycle fatigue tests, exposing the subsurface voids, inclusions and cracks, leading to failure of the MTS. Because of decarburization, or the formation of residual austenite of the surface layer, the ferritic layer is assumed to be formed in the heat treatment process (Fig. 4). Widomski et al. [Wid21] showed that coatings can prevent decarburization of the surface. Hence, further investigations regarding the prevention of decarburization with coatings and the influence on phase transformation and void growth are necessary.

Fig. 4: a) SEM image and b) EBSD plot of the pre-heat-treated flank surface of a tooth, and c) SEM image and b) EBSD plot of the post-heat-treated flank surface of a tooth, adapted from [*Rak23b].

Summary and conclusion

In the current T01 project, the process chain of incremental radial forging, spline extrusion and heat treatment for the production of MTS was analyzed regarding the influence of each process step on the evolution of damage. It was shown that the principles of damage-controlled forming from the 1st and 2nd FP of the TRR188 can be applied on an industrial scale. In each step of the process chain, damage mechanisms like void growth, dependent on stress triaxiality and Lode parameter, and decohesion of inclusions were identified and analyzed. Particularly the collaboration within the TRR188, e.g., the application of the void area quantification methodology using large-area SEM-imaging with automated EDX-scans (B04), the investigation of near-surface damage mechanisms with in-situ experiments (C01) and the knowledge about the damage mechanisms during cold forging (A02), contributed to the understanding of damage in the industrial manufacture of MTS. The close and fruitful cooperation with GKN and Hexagon lead to the continuous exchange of knowledge from the scientific and the applications perspective. However, the detailed analysis of the industrial processes revealed additional challenges, like the influence of the Bauschinger effect on multiple cycles of load reversal, strain localization and local phase transformation during heat treatment on damage. These influencing factors on damage and the product properties need to be investigated in the 3rd FP, to meet the requirements for a damage-controlled process chain and the capability for the quantitative prediction of damage with numerical methods.

Project- and subject-related list of publications

[Bar08] Barsoum, I., 2008. The effect of stress state in ductile failure, Doctoral thesis, KTH Engineering Sciences.

[Cal11] Calcagnotto, M., Ponge, D., and Raabe, D., 2011. On the Effect of Manganese on Grain Size Stability and Hardenability in Ultrafine-Grained Ferrite/Martensite Dual-Phase Steels. The Minerals, Metals & Materials Society and ASM International 2011.

[Gha06] Ghaei, A., Taheri, A.K., Movahhedy, M.R., 2006. A new upper bound solution for analysis of the radial forging process, International Journal of Mechanical Sciences, Volume 48, Issue 11, 2006, Pages 1264-1272, ISSN 0020-7403.

[Gus14] Gusenbauer, C., Reiter, M., Kastner, J., Kloesch, G., 2014. Detection of Non-Metallic Inclusions in Steel by X-ray Computed Tomography and After Fatigue Testing, 11th European Conference on Non-Destructive Testing (ECNDT 2014), October 6-10, 2014, Prague, Czech Republic.

[Hus03] Hustedt, P., 2003. Modular aufgebaute Vorformwerkzeuge für das Schmieden von Langteilen, Doctoral thesis, Universtity of Hannover.

[Li13] Li, Y., Huang, J., Huang, G., Wang, W., Chen, J., Zeng, Z., 2013. Comparison of radial forging between the two- and three-split dies of a thin-walled copper tube during tube sinking, Materials & Design (1980-2015), Volume 56, 2014, Pages 822-832, ISSN 0261-3069.

[Lyc78] Lyckström, S., Nilsson, T., Ståhlberg, U., 1978. The effect of impurity elements on crack formation in forging, Journal of Mechanical Working Technology, Volume 1, Issue 3, 1978, Pages 245-260, ISSN 0378-3804.

[Oha04] Ohata M. & Toyoda, M., 2004. Damage concept for evaluating ductile cracking of steel structure subjected to large-scale cyclic straining, Science and Technology of Advanced Materials, 5:1-2, 241-249.

[Sin21] Singh, V., Khan, R., Bandi, B., Roy, G.G., Srirangam, P., 2021. Effect of non-metallic inclusions (NMI) on crack formation in forged steel, Materials Today: Proceedings, Volume 41, Part 5, 2021, Pages 1096-1102, ISSN 2214-7853.

[Sum22] Summers, J.M., Chakraborty, S., Bartlett, L.N. et al., 2022. On the Effect of Hot Rolling on Inclusion Size and Distribution in a Cast AISI 1070 Steel Railroad Wheel. Inter Metalcast 17, 1277–1295 (2023).

[*Rak23a] Rakshit, T., Gebhard, J., Tekkaya, A. E., 2023. Influence of Die Parameters on the Damage Evolution in Axially Formed Gears. 56th Plenary meeting, International Cold Forging Group.

[*Rak23b] Rakshit, T., Dunlap, A., Kraemer, S., Schulze, A., Aretz, A., Schwedt, A., Tekkaya, A. E., 2023. Damage evolution in axial forming of external splines and quenching operation of the tubular gear shafts. 14th International Conference on the Technology of Plasticity 2023.

[Wid21] Widomski P, Zwierzchowski M, Barełkowski A, Tympalski M., 2021. Case Study of the Effect of Precoating on the Decarburization of the Surface Layer of Forged Parts during the Hot Die Forging Process. Materials (Basel). 2021 Jan 16;14(2):422.