The "Demonstrator" working group was newly created in the second funding period and is based thematically on the findings of the "Performance" working group, which was completed after the first funding period.

The aim of this working group is to select representative components for the process chains used in TRR 188, on which the potential of damage-controlled forming processes to increase performance can be validated.

The tasks consist the definition of components with more complex geometries than in the first funding period for the process chains relevant in TRR 188 and the production of geometrically identical demonstrators on different process routes in order to demonstrate the potential of damage control.

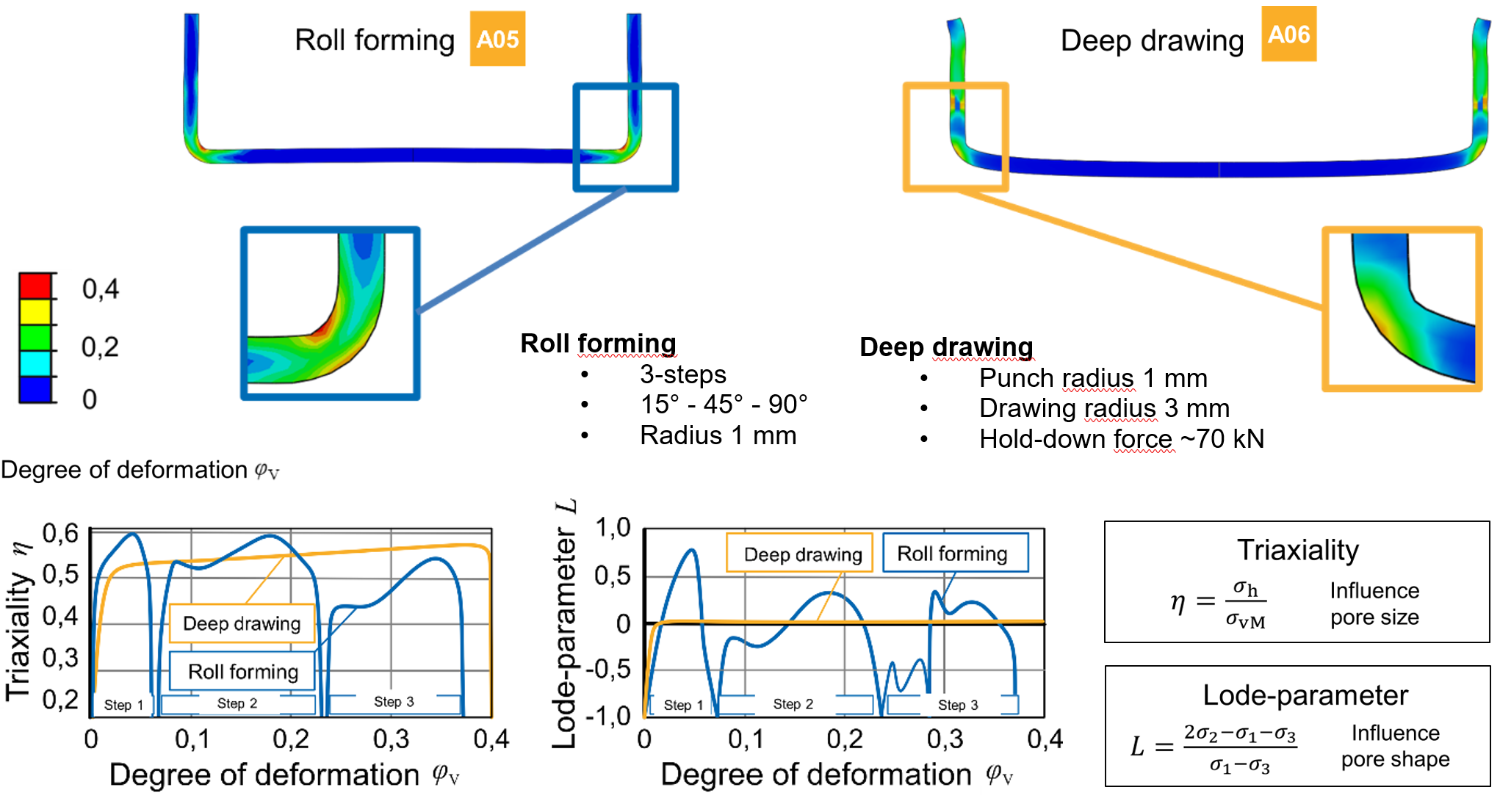

The relevant process chains are defined by the projects located in the A-area, for example the forming processes roll forming, cup-reverse extrusion, transverse extrusion or profile bending. Dynamic, static and cyclic test methods are available for characterising the performance. The targeted influencing of the components is intended to show that the component performance can be increased while maintaining the same geometry or, respectively, that the increased performance can be used for constructive lightweight design. The demonstrators will also be used to show that the new simulation methods developed can be used for systematic technology development to increase performance.

Example from the working group: Load paths in the production of a U-profile.