In materials used for semi-finished rod-shaped products damage, e.g. cast pores or inclusions, already occurs at the very beginning of the manufacturing process. During the caliber rolling process, both damage-increasing mechanisms such as the growth and coalescence of pores as well as damage-repressing mechanisms such as recrystallization and the welding of pores exist. It is known that the occurrence of these effects is influenced by the load path (stress triaxiality and Lode parameter) and temperature increase during the rolling process. Furthermore, these effects can have a significant impact on the product properties by changing the damage accumulation. At present, a deep understanding and observation of these concurrent effects is still challenging. A method, based on which accumulated damage could be predicted and controlled by adjusting the load path, has not been sufficiently developed.

Therefore, the long-term objective of this project is to develop a method for the efficient evaluation of damage evolution during caliber rolling processes with variously designed calibration. As a result, the optimization of the manufacturing strategy should allow a damage-controlled processing of these materials.

|

|

|

|

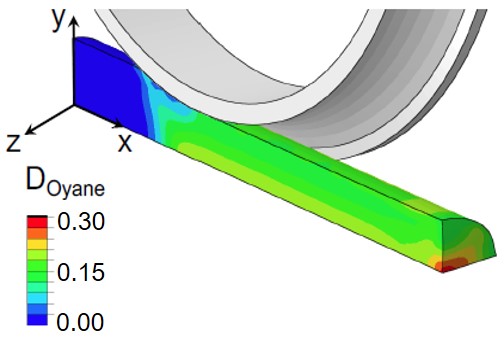

Numerical simulation of caliber rolling |

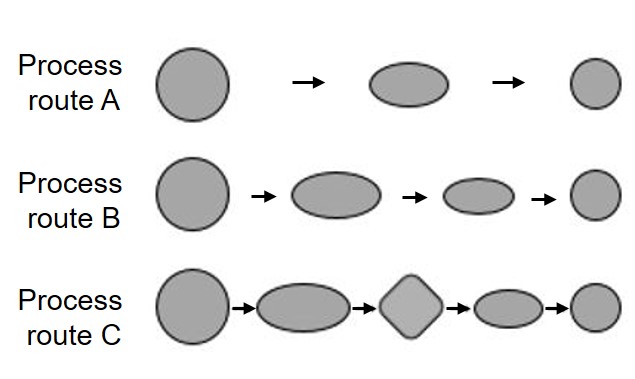

Calibrations designed for the variation of load path |

The first period of this project focuses on the investigation of the damage-increasing mechanisms in terms of generation and growth of pores in dependence of calibration and temperature. First, caliber rolling experiments are planned using the industrially established case hardening steel 16MnCrS5. Afterwards, the material will be subject to extrusion as the next manufacturing procedure in project A02. In order to understand the exact influence of the load path on damage, it is first necessary to find out how the load path varies with process parameters, such as product and caliber geometry, the filling degree of the caliber, the calibration sequence, and the temperature. Furthermore, a numerical analysis of the caliber rolling process with implementation of existing damage criterion such as Cockcroft/Latham will be conducted and experimentally validated to enable a qualitative damage prediction. Damage models with higher complexity, such as Gurson/Tvergaard/Needleman (GTN) and Lemaitre taking stress triaxiality into account are also going to be investigated in coordination with S01. In addition, the criterion of pore closure investigated in project A04 should be integrated, if necessary.

Based on the results obtained by projects A01, A04, and the new damage model developed by project C03 in the first period, strategies for a quantitative damage prediction and targeted damage control for hot forming will be implemented in cooperation with project S01 in the second period.

In the third period of this project, the manufacturing procedures should be optimized (or combined) to minimize damage and innovative materials should be developed based on the insights obtained in the first two periods.

Project leader

Prof. Dr.-Ing. Gerhard Hirt

Institute of Metal Forming (IBF), RWTH Aachen University

Project coordinator

Shuhan Wang M. Sc.

Institute of Metal Forming (IBF), RWTH Aachen University