Summary

Hot forming of aluminum sheets is currently under investigation in research and is increasingly applied in industry, mainly for the production of lightweight complex components for mobility applications. The hot forming of precipitation hardening aluminum alloys, such as from series 6xxx, typically takes place at temperatures above 450 °C, so that thermally activated recrystallization processes occur during the forming process until the component is quenched.

Regardless of the temperature, deep drawing processes incorporate damage-critical load paths, due to the prevailing positive triaxiality, through which voids can nucleate and grow during the forming process. Especially under the aspect of enhancing resulting component performance, it is important to develop process variants that allow for an effective damage control.

Recent work at the IBF on gas-based hot forming [*Bar22] demonstrated the potential to form complex parts with an age-hardenable aluminum alloy, but also revealed the high risk for damage evolution in pure gas-based forming [*Tee23]. In additional preliminary work, supported by CRC lump-sum funds, it was possible to demonstrate that the combination of deep drawing and gas-based forming offers considerable possibilities to influence the load path during hot forming, leading to damage reduction.

This process-related load path manipulation, together with the deliberate selection of forming temperature, soaking times and forming speed facilitate the damage-controlled design of hot forming processes. The influence of microstructural processes, in particular static (SRX) and dynamic (DRX) recrystallization on the damage development during hot forming processes has been shown in the first two funding periods by projects A01, C03 and A07. Additionally, regarding aluminum, it can be stated that damage nucleation at insoluble dispersoids due to particle breakage, and in particular, particle-matrix decohesion at higher temperatures, have been observed before. The underlying damage mechanisms are therefore expected to be similar to a certain extent to the processes investigated in the TRR 188 on 16MnCrS5.

The aim of A10 is to develop guidelines to control the damage evolution during hot sheet metal forming of an age-hardenable aluminum alloy, using the example of AA6010. The influencing factors on the load path in hot forming include both the component geometry and the corresponding blank shape, as well as the process parameters during the forming process. Temperature, forming speed and use of gas pressure are to be used for active process control. The gas pressure serves on the one hand to form features objected to severe thinning e.g. radii and on the other hand as counterpressure for superimposing compressive stresses or for increasing the friction between sheet metal and punch. The use of counterpressure in particular is expected to have positive effects in terms of reducing damage.

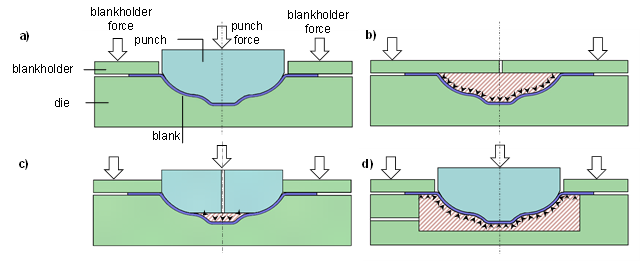

The aim of the work program is to investigate these process options with a focus on influencing the damage, starting with experimental hot forming tests with an axially symmetrical component of AA6010. The influence of complex load paths on damage development will be investigated in four variants of the hot forming process. Besides the reference of conventional deep drawing, the deformation is either exclusively driven by gas pressure or by a combination of deep drawing and gas pressure. The focused process variants are shown in Fig. 1.

|

| Fig. 1: Schematics of experimental tool for a) deep drawing, b) gas-based forming, c) deep drawing + calibration pressure, d) deep drawing with gas counterpressure. |

In each of these process variants, the influence of the thermo-mechanical process parameters will be investigated. For modeling, the GTN damage model, which was adapted for hot forming in the first funding period by C03 and further extended to include the influence of static recrystallization in the second funding period by A07, as well as the damage model developed in C02 will be utilized. Finally, the insights gained from the experiments on the axisymmetric component and the validated damage models will be utilized to design a damage-controlled process for a geometrically more complex cross-die component.

Current state of research and preliminary work

Application of aluminum hot sheet metal forming

Aluminum alloys are known as outstanding candidates for applications demanding lightweight design in automotive and aerospace industry due to their strength-to-weight ratio, fatigue and corrosion resistance. Since the formability of high strength alloys such as alloys of series 6xxx and 7xxx is limited when forming at room temperature, new methods are being developed to form complex geometries with high drawing depths and small radii at higher temperatures [Zhe18]. In hot forming, gas in particular is used as the active medium for shaping. Quick plastic forming (QPF) developed by General Motors [Kra07] enables the production of large numbers of automotive panels. In the QPF process, forming with strain rates of 0.001 s-1 to 0.1 s-1 on AA5083 at 450 °C takes place exclusively by gas pressure. For hollow parts the hot gas HEATforming process was introduced by Hirsch and Amborn [Hir19], where a tube is heated to 500 °C and placed into a cavity. Both ends of the tube are sealed and axially fed into the cavity. Simultaneously, inner gas pressure forms the component in the cavity. An additional development is the hot die forming (HDF) process as described by [Nia19] where a work piece is heated to solution heat treatment temperature. The increased temperature makes it possible to reduce the gas pressures for forming the contours, so that thinning can be reduced compared to super plastic forming. A combination of mechanical deep drawing with gas-based forming processes is Hybrid Super Plastic Forming (HSPF) presented by [Liu12]. Due to the improved formability at high temperatures, hot deep drawing can reduce thinning through increased material draw-in, and in combination with gas support, it can increase geometric complexity.

Recrystallization in aluminum alloys

In the first two funding periods, the recrystallization mechanisms, and their effect on damage evolution for a case hardening steel were investigated. As the hot sheet metal forming of aluminum takes place above temperatures of 450°C recovery and recrystallization will occur. Since hot rolling, hot extrusion and hot stamping are common forming processes for aluminum components, recrystallization and the accompanying effects on microstructure are well known. An overview is given by [Lv20] who describe the different recrystallization mechanisms in aluminum. Three types of dynamic recrystallization (DRX) occur in aluminum: Discontinuous (DDRX), continuous (CDRX) and geometric (GDRX) recrystallization. While DDRX can occur in pure aluminum and at lower strain rates and temperatures due to the high mobility of grain boundaries without the Zener drag, CDRX is expected during the hot sheet metal forming due to the high stacking fault energy of aluminum. In CDRX, the dislocations form a subgrain structure in the original grains. The recrystallized microstructure is formed by the rotation of the subgrains and the formation of high angle grain boundaries (HAGBs). The expected link of recrystallization to damage in aluminum alloys has yet to be investigated.

Damage in aluminum alloys at elevated temperatures

As demonstrated by [Aga03], triaxiality significantly influences the damage development of voids at inter-metallic particles in aluminum. They conducted notched tensile tests at room temperature on AA6061 samples with various notch radii. In regions where the stress state is predominantly triaxial, cracked Fe-rich intermetallic particles were observed along with the growth of microvoids around these intermetallic particles. In contrast, standard tension test specimens without notches did not exhibit significant void growth around cracked particles. The design of the load path with respect to triaxiality is therefore crucial for damage development and can also be utilized for damage-controlled hot sheet metal forming of aluminum.

In aluminum alloys, two different ductile damage mechanisms occur. Either particle fracture or interface decohesion dominates, depending largely on the plastic behavior of the matrix. These findings correspond to the CRC’s findings on the case-hardening steel 16MnCrS5. As the differences of the mechanical properties of the matrix phases remain low, damage initiates at the non-metallic inclusions. For aluminum [Bab04] proposes a model that analyzes the dominant damage mechanisms in model composites with aluminum alloy matrices and spherical zirconia/silica reinforcement. In hot forming of aluminum, the matrix becomes softer, but so do the intermetallic particles, making interface decohesion dominant in most cases. Solution heat treatment (SHT) ensures that precipitates dissolve and diffuse through the matrix material, thereby reducing the chance of forming microvoids around second phases during plastic deformation. Nevertheless, some particles are not affected by SHT and remain in the matrix. [Wan11] investigated the hot formability of AA2024 at elevated temperatures. They found that ductility, as well as formability in cup tests, increase with rising temperature. Fracture surfaces exhibit different modes of fracture depending on the temperature. Tensile samples deformed at temperatures of 350°C show a ductile damage consisting of microvoid nucleation, growth, and coalescence similar to a damage mechanism at room temperature. At higher temperatures, above 480°C and slightly below the solution temperature of 493°C, intergranular fracture was the dominant mechanism due to very low-strength grain boundaries. [Las06] investigated the effect of homogenization conditions, particle morphology, and temperature on the formability in an extrusion process of AA6060 and AA6005A. Precipitates and inclusions have a significant influence on the ductility of the alloy and damage evolution. In AA6xxx alloys, detrimental elongated β-type particles transform into α-type particles through SHT. At high temperatures, interface decohesion becomes the primary damage mechanism. They assumed that damage primarily originates from AlFeSi second-phase particles at room temperature. Interrupted tensile tests at 550°C revealed damage at large strains, with nucleation occurring through debonding of the particle-matrix interfaces. Fracture surfaces of AA6005A showed a classical ductile profile with dimples, some of which contained particles identified as β-Al5FeSi. At temperatures above the solution heat treatment temperature, damage associated with local grain boundary melting occurs in AA6060 but not in AA6005.

For comprehensive damage modeling, void nucleation, growth and eventual coalescence must be considered. Numerous studies have shown that the porous plastic damage GTN model performs well in predicting ductile damage in metals. However, in the field of hot forming of aluminum sheets, there is still a lack of research on damage evolution. [Li21] conducted hot uniaxial tensile tests with AA7075-T6 at different temperatures and strain rates to calibrate the damage parameters. The calibrated GTN model predicts stress-strain curves with good agreement for different temperatures and strains. [Yin19] used a calibrated GTN model to predict a Thermal Forming Limit Diagram (TFLD) of AA7075 at elevated temperatures. In hot Nakajima tests, the model was verified, demonstrating the GTN model's capability to predict TFLDs. However, the classical GTN model is not specifically designed for hot forming and requires a new parameter set for each temperature. The GTN model developed by [Imr20] in the first and second funding periods of TRR 188, which considers dynamic and static recrystallization, requires only one parameter set and is thus suitable for hot forming as well. It includes a new coupled DRX-damage nucleation criterion taking DRX and the stress state into account so that the damage induced in hot forming processes can be predicted. More recently the GTN model was further extended by [*Hei23] to account for SRX during interpass times typically occurring in multi-stage hot forming processes. It could be shown that recrystallization can reduce damage and should therefore be considered in process design.

Preliminary work

Hot sheet metal forming of aluminum

At the IBF complex experimental setups have been developed that enable pure gas-based as well as hybrid deep drawing and gas-supported forming of benchmark parts. The principle investigator David Bailly has been supervising this work as chief engineer of the IBF. In the hot forming processes, the blank is positioned between heated dies and brought up to the solution heat treatment (SHT) temperature. After annealing for 15 minutes, the blank is rapidly formed using gas pressure. Following the forming process, the components are quenched in water. Depending on the research question, the formed components can be subjected to further artificial aging.

In [*Tee23], a cross-die specimen and a round cup of the age-hardenable AA6010 were processed through gas-based hot forming. Micrographs of the initial microstructure show α-AlFeMnSi inclusions and primary Mg2Si phases identified as non-metallic particles. SEM images also reveal voids at the non-metallic inclusions, highlighting AA6010 as a promising candidate for damage investigations. It is known that the sizes of intermetallic particles, typically ranging from 1 µm to 10 µm, have a direct effect on formability. Larger particles can act as stress raisers and lead to localized areas of reduced ductility. Finer dispersoids of AlFeMnSi help stabilize the microstructure during hot forming, preventing excessive grain growth at high temperatures. After SHT, a fully recrystallized fine-grained microstructure was established. Microstructural investigations at the arm corner of the formed cross-die specimen show elongated grains in the direction of sheet stretching and a slightly finer-grained microstructure, along with an increased amount of subgrain boundaries within individual grains, indicating the occurrence of CDRX.

For the process design in aluminum hot sheet metal forming the thermal process control is important, because it is decisive for the mechanical properties of the components after heat treatment. This field is a main focus of the research work of the principle investigator Emad Scharifi. In an aluminum hot sheet metal forming process without gas forming, [*Sch19] has investigated the influence of solution heat treatment parameters including heating rate, SHT temperature, soaking time and cooling rate on the resulting mechanical properties and the strengthening and formability behavior for AA6082 and AA7075. They found that high heating as well as cooling rates improve the mechanical properties. The findings can be used to optimize the process steps of solution annealing and quenching. The precipitation microstructure of age-hardenable Al-Mg-Si aluminum alloys mainly determines the mechanical properties. During artificial aging, the formation of finely dispersed second-phase (Al-)Mg-Si particles along with further precipitation of silicon and magnesium into these particles result in the strengthening of the material. The precipitation sequence and kinetics depend on temperature and alloy composition. The temperature control in the first process steps, solution annealing and quenching affect the formation of precipitates during the artificial aging treatment. In [*Sch21] the microstructure behavior during the thermo-mechanical process as well as the mechanical properties of an AA7075 hat profile are investigated after undergoing a high and low cooling rate during quenching, respectively. It was shown, that in artificial aging the strength enhancing fine and dispersed precipitates only form after high cooling rates. Further investigations of AA6082 and AA7075 considering the deformation properties under dynamic tensile loading conditions and microstructure of the alloys after different cooling rates in [*Sch20] showed, that at low quenching rates, the nucleation of precipitates and the segregation of alloying elements at grain boundaries are promoted, leading to a significant decrease of the ultimate tensile strength in dynamic tensile tests. Similarly, [*Saj22] demonstrates that high cooling rates yield improved fatigue properties compared to low cooling rates. For the design of a damage-controlled forming process of age-hardenable aluminum alloys, particular emphasis should therefore be placed on differentiating the influence of damage and artificial aging on performance.

Process modelling of gas-based forming processes

For a knowledge-based design of damage-controlled forming processes, the ability to model the processes and the damage evolution is important. Gas-based forming processes at high temperatures are challenging in finite element (FE) simulations due to the complex temperature and strain rate-dependent material behavior. Additionally, the thermomechanical and tribological interactions between the tools, workpiece, and active media change over the course of the process and affect the formability and material properties. In the case of gas-based hot forming processes with more complex geometries featuring sharp edges, corners, stepped features, and local protrusions, as developed in [*Bar22], it is apparent that due to thinning and draw-in of the blank, linear quadrilateral elements currently used for discretization are geometrically insufficient for modeling. To achieve reliable modeling, a meshing approach or an adaptive remeshing approach needs to be developed for modeling and simulating fine geometrical features.

For reliable FE simulations of hot stamping processes, in addition to an appropriate discretization, an accurate thermo-mechanical material description is essential. Typically, tensile tests or hydraulic bulge tests are employed for this purpose. Material characterization with hydraulic bulge tests has the advantage to go beyond uniaxial tension and allows for high strain levels. However, when the high temperatures of hot forming are transferred to the material testing, hydraulic oil is not suitable as a pressure medium. Therefore, the hot gas-based bulge test was developed at the IBF and has been continuously improved, most recently by [*Tee22]. The hot gas bulge test is capable of assessing biaxial forming limits at elevated temperatures. Additionally, for the determination of FLDs of a 6xxx aluminum alloy within the solution heat treatment temperature under gas-based hot forming process conditions, a double-layer bulge test was developed. In this test setup, a thick carrier sheet acts as a punch. The specimen incorporates varying hole geometries to obtain different strain paths on both sides of the FLD. A digital image correlation (DIC) system is employed to monitor specimen deformation as well as the local major and minor strains.

|

|

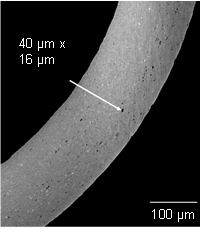

Fig. 2: MicroCT image showing voids in a gas-calibrated component radius of AA6010. |

For the third funding period, preliminary work was conducted on damage development in aluminum hot sheet metal forming. In a first step, the goal was to determine whether and to what extent damage occurs in the hot sheet metal forming process as currently conducted at the IBF. To achieve this, the cross-section of a radius of a hot-formed component was examined using microCT in collaboration with B04. As seen in Fig. 2, voids in the material are evident. It is also clear that the voids in the outer radius are more numerous and larger compared to those in the inner radius. Additionally, they are elongated in the tensioned area of the wall. This emphasis that in aluminum hot sheet metal forming, the stress state significantly influences the development of damage.

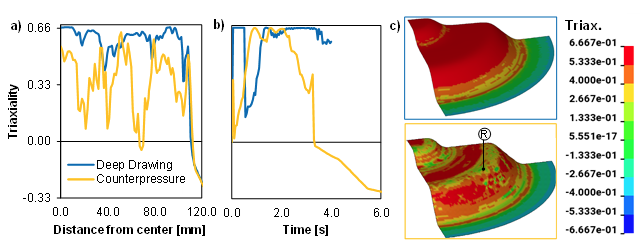

In a numerical study, it was therefore investigated to what extent the triaxiality can be influenced in the forming processes of deep drawing and deep drawing with gas counterpressure. The simulations were conducted on quarter-symmetric components in the simulation software LS-Dyna using a fully-integrated shell formulation. Material properties of AA6010 were utilized for the plasticity description. Initially, suitable blankholder forces and punch velocities were determined to minimize the maximum thinning in the forming processes. A maximum thinning of approximately 21% is achieved with a blank holder force of 5 kN and a punch velocity of 10 mm/s. As an example, the comparison between the pure deep drawing process and a deep drawing process where gas counterpressure is introduced at half of the punch stroke with 22 bar/s is shown. In Fig. 3a), the triaxiality along the x-coordinate, starting at the center of the cup and extending to the flange over a punch stroke of 90%, is illustrated. It is evident that the triaxiality throughout the entire component is lower when using gas counterpressure compared to pure deep drawing.

|

| Fig. 3: Triaxiality a) at a radius R over time b) over the x-coordinate at 90 % punch movement, c) Triaxiality of component formed with counter pressure (top) and deep drawing only (bottom) at full punch stroke |

As an illustration Fig. 3a shows the temporal evolution of triaxiality at a node at the outer radius of the component, depicted in Fig. 3c. This point experiences a change in load from positive to negative triaxialities towards the end of the forming process. When the component is further subjected to gas counterpressure, the triaxiality continues to decrease. The simulation study clearly indicated that the timing of introducing gas counterpressure is crucial for the triaxiality evolution. It should be noted that introducing gas counterpressure too early in the forming process can lead to an early change in load, initially to negative and subsequently back to positive triaxialities.

Conclusion

There is a wide range of aluminum hot sheet metal forming processes, which are typically designed using Forming Limit Diagrams. However, these diagrams are insufficient for describing the complex micromechanical processes involved in damage development. In aluminum hot sheet metal forming, damage modeling has seen limited application to date. The GTN model is partially employed for damage modeling, but without extensions, it is less suitable for hot forming processes, as evidenced by various parameter sets for various temperatures. Comprehensively validated finite element (FE) models are available at IBF, which can accurately describe the hot gas-based sheet metal forming process, but currently do not account for damage. The damage mechanisms observed in Al-Mg-Si alloys are similar to those investigated in the TRR 188 for the case of 16MnCrS5 steel, including particle breakage and particle-matrix decohesion. Therefore, the damage models developed for hot forming of 16MnCrS5 in TRR 188 are ideal candidates to be utilized and transferred to the new forming process and material.

As the preliminary work has shown, gas counterpressure is an effective means to influence the load path, resulting in lower triaxialities in parts of the component during forming compared to pure deep drawing processes. The process of hot gas-supported deep-drawing provides new actuating variables to control damage, namely the gas-pressure, the temperature and the process-timing. This allows the deliberate reduction of damage, either globally or locally based on the load scenario in the application.

Project- and subject-related list of publications

| [Aga03] | Agarwal, H., Gokhale, A.M., Graham, S., Horstemeyer, M.F., 2003. Void growth in 6061-aluminum alloy under triaxial stress state. Materials Science and Engineering: A 341, pp. 35–42,DOI: 10.1016/S0921-5093(02)00073-4. |

| [Bab04] | Babout, L., Brechet, Y., Maire, E., Fougères, R., 2004. On the competition between particle fracture and particle decohesion in metal matrix composites. Acta Materialia 52, 4517–4525, DOI: 10.1016/j.actamat.2004.06.009. |

| [*Bar22] | Baru, N.K., Teeuwen, T., Bailly, D., Hirt, G, 2022. A Novel Benchmark Test for Validating the Modelling and Simulation Methodology of Modern Gas-Based Hot Sheet Metal Forming Processes. In: Proceedings of the 12th International Conference and Workshop on Numerical Simulation of 3D Sheet Metal Forming Processes, 1(55). pp 785–801, DOI: 10.1007/978-3-031-06212-4_71. |

| [*Hei23] | Heiser, A., Gerlach, J., Bailly, D., Hirt, G., 2023. Investigation of the Influence of Static Recrystallization on Void Evolution After Hot Compression Forming. In: Production at the Leading Edge of Technology. Lecture Notes in Production Engineering, pp. 335-344, DOI: 10.1007/978-3-031-47394-4_33. |

| [Hir19] | Hirsch, J., Brünger, E., Keller, S., Amborn, P., Kipry, K., 2019. Hot forming of Al-Mg-Mn alloys for light-weight car design. In: International Conference on Aluminium Alloys, Aachen. |

| [Imr20] | Imran, M., Afzal, M.J., Buhl, J., Bambach, M., Dunlap, A., Schwedt, A., Aretz, A., Wang, S., Lohmar, J., Hirt, G, 2020. Evaluation of process-induced damage based on dynamic recrystallization during hot caliber rolling. Production Engineering 14, pp. 5–16, DOI: 10.1007/s11740-019-00932-0. |

| [Kra07] | Krajewski, P.E., Schroth, J.G., 2007. Overview of Quick Plastic Forming Technology. Materials Science Forum 551-552, pp 3–12, DOI: 10.4028/www.scientific.net/msf.551-552.3. |

| [Las07] | Lassance D., Fabergue, D., Dellany, F., Pardoen, T., 2007. Micromechanics of room and high temperature fracture in 6xxx Al alloys. Progress in Materials Science 52, pp. 62–129, DOI: 10.1016/j.pmatsci.2006.06.001. |

| [Li21] | Li, X., Xu, M., Zhang, Z., 2021. Hot damage evolution in a high strength aluminum alloy during hot forming: a study using the Gurson–Tvergaard–Needleman model. Journal of Materials Research and Technology 14, pp. 1366–1376, DOI, 10.1016/j.jmrt.2021.07.066. |

| [Liu12] | Liu, J., Tan, M.-J., Jarfors, A.E.W., Lim, S.C.V., Fong, K.-S., Castagne, S., 2012. Greener manufacturing: Superplastic-like forming. Journal of Physics: Conference Series 379, 12034, DOI: 10.1088/1742-6596/379/1/012034. |

| [Lv20] | Lv, J., Zheng, J.-H., Yardley, V.A., Shi, Z., Lin, J., 2020. A Review of Microstructural Evolution and Modelling of Aluminium Alloys under Hot Forming Conditions. Metals 10 1516, DOI: 10.3390/met10111516. |

| [Nia19] | Niazi, M.S., Amborn, P., Lamers, E., Hirsch, J., 2019. Hot Die Forming - Flat (HDF-F Al): An innovative hot forming technology for extreme lightweight in aluminum sheet alloys. IOP Conference Series: Materials Science and Engineering 651, DOI: 10.1088/1757-899X/651/1/012003. |

| [*Saj22] | Sajadifar, S. V., Scharifi, E., Wegener, T., Krochmal, M., Lotz, S., Steinhoff, K., Niendorf, T., 2022. On the low-cycle fatigue behavior of thermo-mechanically processed high-strength aluminum alloys. International Journal of Fatigue, 156, DOI: 10.1016/j.ijfatigue.2021.106676. |

| [*Sch21] | Scharifi, E., Savaci, U., Kavaklioglu, Z. B., Weidig, U., Turan, S., Steinhoff, K., 2021. Effect of thermo-mechanical processing on quench-induced precipitates morphology and mechanical properties in high strength AA7075 aluminum alloy. Materials Characterization, 174, 111026, DOI: 10.1016/j.matchar.2021.111026. |

| [*Sch20] |

Scharifi, E., Sajadifar, S. V., Moeini, G., Weidig, U., Böhm, S., Niendorf, T., Steinhoff, K., 2020, Dynamic Tensile Deformation of High Strength Aluminum Alloys Processed Following Novel Thermo-Mechanical Treatment Strategies. Advanced Engineering Materials, 22, 2000193, DOI: 10.1002/adem.202000193. |

| [*Sch19] | Scharifi, E., Knoth, R., Weidig, U., 2019. Thermo-mechanical forming procedure of high strength Aluminum sheet with improved mechanical properties and process efficiency. In: Procedia Manufacturing, 29, pp. 481 - 489, DOI: 10.1016/j.promfg.2019.02.165. |

| [*Tee23] | Teeuwen, T., Baru, N.K., Bailly, D., Hirt, G., 2023. Investigation on evolution of microstructure and mechanical properties of heat-treatable 6010-S aluminium alloy during gas-based hot sheet metal forming process. IOP Conference Series: Materials Science and Engineering 1284, 12005. DOI: 10.1088/1757-899X/1284/1/012005 |

| [*Tee22] | Teeuwen, T., Baru, N.K., Tilly, K.J., Bailly, D., Hirt, G., 2022. Development of a high-temperature double-layer bulge test for failure prediction in gas-based hot forming of a high-strength aluminium alloy. IOP Conference Series: Materials Science and Engineering 1238, 12049, DOI: 10.1088/1757-899X/1238/1/012049. |

| [Wan11] | Wang, L., Strangwood, M., Balint, D., Lin, J., Dean, T.A., 2011. Formability and failure mechanisms of AA2024 under hot forming conditions. Materials Science and Engineering: A 528 pp. 2648–2656, DOI: 10.1016/j.msea.2010.11.084. |

| [Yin19] | Ying, L., Gao, T., Rong, H., Han, X., Hu, P., Hou, W., 2019. On the thermal forming limit diagram (TFLD) with GTN mesoscopic damage model for AA7075 aluminum alloy: Numerical and experimental investigation. Journal of Alloys and Compounds 802, pp. 675–693, DOI: 10.1016/j.jallcom.2019.05.342. |